Motor soft starters play a key role in various industries by ensuring motors start smoothly and efficiently. By gradually increasing voltage, these devices reduce equipment wear and lower energy consumption. Understanding their operation and benefits helps us make informed decisions about their use. This article provides an overview of the basics, benefits, and selection of motor soft starters.

Understanding The Basics Of Motor Soft Starters

Motor soft starters offer a controlled method to start electric motors, providing several advantages over traditional starters. Here’s an overview of what they are and how they function:

What is a motor soft starter, and how does it work?

A motor soft starter gradually increases the voltage to a motor, enabling a smooth start. This process minimizes mechanical stress on the motor and electrical stress on the power system, resulting in more stable operation.

What are the main components of a motor soft starter?

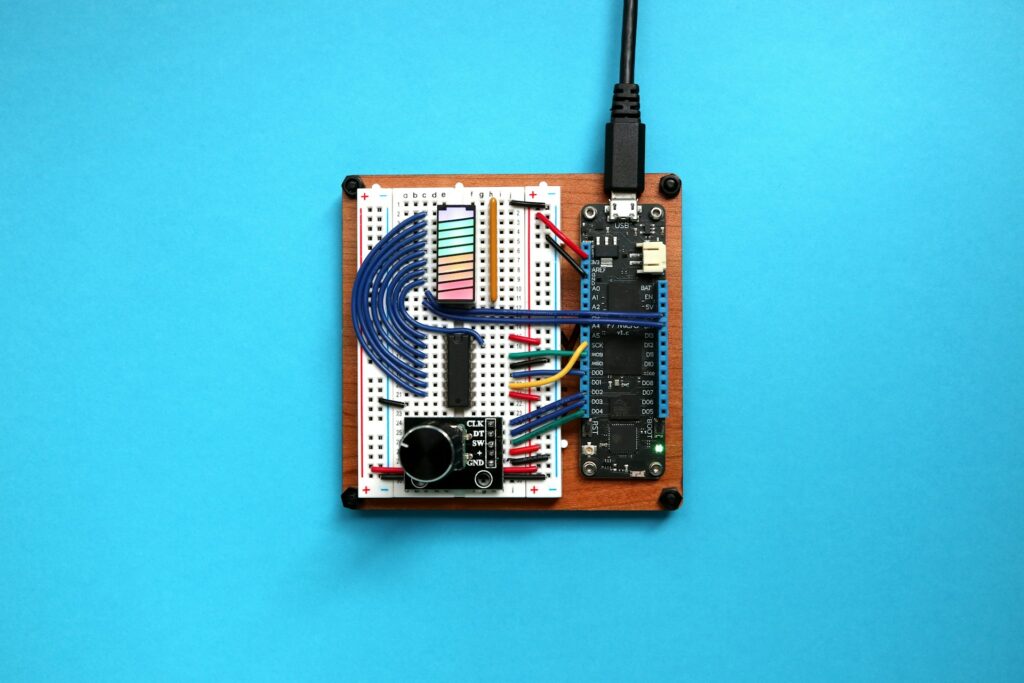

Key components include:

– Control Units: Manage the starting process.

– Power Electronics: Handle the electrical load.

– Bypass Contactors: Ensure efficient operation once the motor reaches full speed.

How does a soft starter differ from a traditional motor starter?

Unlike traditional starters that provide full voltage immediately, soft starters apply voltage gradually. This approach reduces the initial power surge, leading to less wear on the motor and connected machinery. By grasping these fundamentals, we can appreciate the importance of motor soft starters in enhancing motor performance and extending equipment lifespan.

Why Use A Motor Soft Starter?

Motor soft starters offer several benefits that make them a preferred choice over traditional starters in many applications.

What Are The Benefits Of Using A Motor Soft Starter?

Motor soft starters protect motors from electrical and mechanical stress by ramping up the voltage gradually. This gradual increase reduces the risk of damage to motor components, which can extend the motor’s lifespan and lower maintenance costs. Additionally, soft starters help save energy by minimizing high inrush currents, leading to reduced energy consumption during motor startup and potential cost savings over time.

Another advantage is the reduction of mechanical shock on machinery. Traditional starters can cause a jolt when starting motors, leading to wear on connected equipment. Soft starters provide a smooth transition to full speed, protecting both the motor and the machinery it drives.

How Does A Soft Starter Improve Motor Performance?

Soft starters enhance motor performance by ensuring a stable and controlled startup. This reduces voltage dips in the power supply, which can disrupt other connected systems. A steady start allows the motor to reach its optimal performance level without unnecessary strain.

Furthermore, by managing the startup process, soft starters also decrease the noise and vibration associated with motor starting. This results in quieter operations and contributes to a more comfortable working environment in industries like HVAC and manufacturing, where noise can be a significant concern.

What Industries Commonly Use Motor Soft Starters?

Motor soft starters are widely used in industries where equipment reliability and efficiency are critical. In HVAC systems, they manage the startup of large fans and compressors, reducing energy usage and wear. Water treatment facilities benefit from soft starters by enabling the smooth operation of pumps, minimizing the risk of water hammer and system overloads.

In manufacturing, where consistent and reliable motor operation is essential, soft starters ensure machinery starts smoothly, reducing downtime and maintenance needs. This is particularly important in processes that require precision and timing, such as assembly lines and conveyor systems.

How To Choose The Right Motor Soft Starter

Selecting the appropriate motor soft starter involves considering several factors to ensure optimal performance and compatibility with specific applications.

What Factors Should You Consider When Selecting A Motor Soft Starter?

When choosing a motor soft starter, consider the motor’s size and load requirements. The starter must handle the motor’s power demands to ensure efficient operation. Additionally, the operating environment is important. For instance, in harsh conditions, a soft starter with robust protective features may be necessary such as overload protection, phase loss detection, and short-circuit protection. These features help safeguard both the motor and the starter from potential damage, ensuring a longer service life and reducing maintenance needs.

How Do You Determine The Appropriate Size And Rating For A Soft Starter?

To determine the correct size and rating, assess the motor’s full-load current and the application’s specific requirements. It’s essential to match the soft starter’s capacity with the motor’s electrical demands. Reviewing the motor’s specifications and considering the operational environment will aid in making an informed choice.

Consider the motor’s duty cycle as well. Motors that frequently start and stop require a soft starter rated for higher thermal capacity to handle the increased electrical demands. This ensures the starter operates effectively without overheating or sustaining damage.

What Features Should You Look For In A Motor Soft Starter?

Look for features like adjustable start and stop times, which provide flexibility in managing motor operations. This is particularly useful in applications with varying loads. Additionally, diagnostic capabilities are valuable for real-time monitoring of motor performance, helping to identify potential issues before they become significant problems.

The ability to integrate with existing control systems is another important feature. A soft starter that can communicate easily with other devices in the system can enhance overall efficiency and streamline operations. This is especially important in complex industrial setups where coordination between different systems is essential.

Installation And Maintenance Of Motor Soft Starters

Proper installation and regular maintenance of motor soft starters are vital to ensuring their long-term performance and reliability.

How Is A Motor Soft Starter Installed?

Installing a motor soft starter involves several key steps. First, ensure the power supply is compatible with the starter’s requirements. Connect the starter to the motor according to the manufacturer’s guidelines, typically wiring the control and power circuits carefully.

Once connected, configure the starter settings to match the motor’s parameters, such as voltage and current limits. This ensures the soft starter operates within its designed capabilities, providing optimal performance. It’s also essential to test the installation thoroughly, verifying that the motor starts smoothly and that all protective features function correctly.

What Are The Ideal Practices For Maintaining A Motor Soft Starter?

Regular maintenance keeps a motor soft starter in good working condition. Periodically inspect the starter for signs of wear or damage, such as loose connections or overheating components. Cleaning the unit to remove dust and debris can also help prevent potential issues.

Updating the starter’s firmware and software, if applicable, ensures it operates with the latest features and improvements. Maintaining detailed records of maintenance activities and any issues encountered can assist in identifying patterns and preventing future problems.

What Common Issues Might Arise With Soft Starters, And How Can They Be Resolved?

Common issues with soft starters include overheating, incorrect settings, and component failures. Overheating can often be resolved by ensuring adequate ventilation around the starter. Incorrect settings may require recalibration to match the motor’s specifications.

Component failures might necessitate replacing damaged parts. Regularly checking and testing the starter can help identify these problems early. In cases of persistent issues, consulting with the manufacturer’s technical support can provide guidance and solutions tailored to the specific starter model.